So I started the tear-down of the bike last week. The Crew at Honda Suzuki of Salt Lake stayed late to help me get the street stuff off and get ready to put the race stuff on. I really appreciate the shop space and the help. You know you've got a good group of people when they're willing to stay late after a full day of work--in Jeff's case, he's a new hire that hadn't even technically started working at HSSL yet, and he's already puttin' in work after hours. Good guys, all of 'em. And, they work amazingly quick:

A couple days later, I started putting some of the race stuff on (and continued to remove all that wasn't totally necessary to make the bike go or stop fast). To open up my workspace, I removed the airbox and radiator. I gotta say, I got a lot of practice unplugging electrical connectors of all sorts while doing this.

Here's how it went:

Installed the Motion Pro Revolver Quickturn Throttle kit (well, just the cables actually; I'm waiting on some handlebars before I put the throttle tube on). I must note, I wasn't smart enough to attach the cables without removing the throttle bodies from the intake boots, so I had to take 'em off:

Woodcraft Clutch Side engine case protector, this was super straightforward.

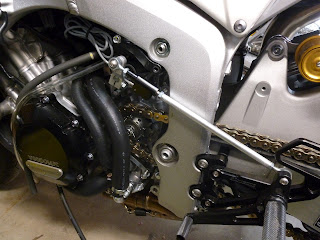

Woodcraft Stator Side engine case cover. This was a little more complicated, but not too hard. Just keep all the hardware and bits sorted out when you're reassembling

Woodcraft Frame Sliders, again wicked easy to install.

Woodcraft Sharkfin sprocket protector. I chose to tap threads directly into the swingarm, as opposed to use the supply "riv-nuts", because I've seen so many of those come loose and fall off.

Keyless Ignition. This was pretty easy, just a 30A switch that I wired into the two wires that went into the stock ignition switch. To get the stock switch out, I just drilled the heads off the tamper-proof bolts. Basic hardware and some scrap sheet metal finished the mount for the new switch. Electrical tape and a bit of silicone made it water resistant.

Then a Vortex keyless gascap was added, too.

On to the Leo Vince exhaust. This actually wasn't very hard, despite the instructions being in Italian. Leo was really helpful to etch each part number into each specific exhaust part (there are a lot!), so it was just a matter of matching the numbers to the pictures. IMPORTANT! Make sure to use new header gaskets every time you take the little header mounts off! I did have to trim a bit of the CBR's frame away at the lower tailpipe mount (near the lower shock linkage). It was a very small protrusion that didn't allow the bracket to sit correctly.

The PAIR system removal is just something to do to save a bit of weight and give yourself some room around the engine. I just took the parts off and replaced them with some homemade aluminum plates, sealed with gasket maker.

I switched the gearing over to an EK 520 size chain, going with corresponding Vortex 15 tooth front sprocket (one down from stock) and a Vortex 42 tooth rear sprocket (stock size). I also have a 43t and 44t in the spares box to fit specific track configurations. I'm guessing at the ratios, but because of some magazine tests I read, it's at least an educated guess. It's a good idea to safety wire the front sprocket, because these aftermarket versions don't have the thick rubber damping thing that reduces vibration.

Hand and foot controls are handled by Woodcraft Clip-ons and Rearsets. When installing the clip-ons, I moved the starter/kill switch to the left side and fabricated a little bracket for my homemade Bazzaz fuel map switch (my switch cost $4, the Bazzaz one is $70!!)

Once I installed the rearsets, I modified the rear brake reservoir--actually, I just removed it. You need to keep a little bit of fluid in the system, so get some Tygon tubing (get the right flavor, sold at kurvygirl, or McMaster-Carr). I plugged the end with an airbox plug from a Honda Ruckus (I think this is a pretty universal plug amongst Hondas, because Honda Suzuki of Salt Lake had one in stock). Drill a hole in the top to vent the system (to accommodate heat expansion of the fluid). I made a little "diaphragm" out of a rubber glove, but that didn't hold up very well to small fluid splashes, so I ended up using electrical tape with a little air cavity (I'll need to replace the tape every weekend to keep degradation to a minimum).

I needed to get rid of the stock front fairing stay, because it doubles as an intake noise diffuser (so it's HUGE) and limited my lever and handle bar position to only stock. This took a bit of work, because I didn't want to buy an aftermarket fairing stay. So I first fabricated a speedometer/tip-over/wiring mount. We have a Bridgeport at my work and my friend was so kind as to teach me how to use it, so I built this little thing:

It worked out awesome and gave me some room at the front of the bike (which on Hondas, there is not very much of). My plan was to simply bend a piece of tube into a U and use that as the fairing stay. After about 4 tries, I couldn't get the bends correct, so I quit. I remember seeing an on-board video with Casey Stoner that seemed to have "stays" laminated right in the bodywork, next to the windscreen. So, I decided to try it. I had a bit of scrap aluminum flat bar in my garage, so I cut a couple short pieces and bent them to fit the contours of the fairing. I then screwed them to the fairing with some self-tapping screws and laminated them in with a few layers of fiberglass. Once dry, I removed the screws and filled the holes with body-filler. The end result is a super clean cockpit without the need for a traditional, somewhat fragile aftermarket fairing stay. This is a pic taken from inside the upper fairing, with air intake hole at the bottom.

When you remove the stock fairing-stay/intake diffuser, you're left with some holes on the intake. I just taped them up with duct tape (I covered the inside glue of the tape, so it wouldn't collect dirt in the intake). Some companies offer metal plates made specifically to cover these holes, but I tape works for me. Also, I cut out the little wing inside the intake that is meant to deflect air up into the stock intake diffuser. You can find how to access these parts by searching for "Gutted Intake" on the 600rr.net forum. I DID NOT gut the whole thing, just the part that deflects air up.

For suspension, I deferred to my friend Jason at Corporate suspension. He's the man and helped me win the Nov-GTU championship in 2010. He took 2011 off (this is when Aaron Clarke stepped in and helped me out quite a bit with suspension, riding, and racecraft). Anyway, Jason's back for 2012! He built up the forks with RaceTech valves and a custom shim-stack and stuck in some .95 weight springs (down from 1.0 stock). In the rear, we went with an Ohlins TTX with hydraulic preload adjustment, custom valving, and a .95 spring. Out of the box, the preload adjuster inlet on the rear shock was in the way of the swingarm mounts, so I had to back off the preload (and counted the turns!) all the way and spin the whole preload assembly 1/8 of a turn. After that, it dropped right in.

My most unfavorite thing about these bikes is the electronics. Yeah, I like being able to adjust the fuel map of my bike on my laptop and I really dig the quick shifter, but there are just so many damn wires on these things. Anyway, on went a Bazzaz Z-Fi +QS (quickshifter) unit; and with it, came more wires... Honestly, hooking it up was really easy, it's just that finding a place for, you guessed it: all the wires was a huge pain. I also installed a Z-AFM, which is Bazzaz's self mapping thing. It's not a total replacement for dyno-tuning, but it is effective. Once all the wires were routed, I mounted everything in the tail section.

I also had the stock ECU reflashed by ECUnleashed. This procedure eliminates a bunch of factory implemented limitations (throttle openings, ignition retard, fuel shut-off on deceleration, etc.) The ECUnleashed reflash made a Bazzaz Z-Bomb Ignition Module unnecessary, but if don't get a reflash, you should install a Z-Bomb.

The Quickshifter was a bit of a pain in the ass. One, because the Woodcraft rearsets change the direction of shift linkage--which I didn't know ahead of time, so I ordered the wrong style switch. For reverse shift (1 up, 5 down), I needed a "Push" type switch with the Woodcraft, as opposed to the "Pull" type I ordered before I knew the Woodcrafts changed the direction. I called Bazzaz and Jason there was really helpful and sent out a Push switch in exchange for the Pull switch I sent back. I also had to cut, drill and tap the shift rod to shorten it up and make room for the quickshift switch. This was a bit of a process of building a jig on the drill press and praying I didn't screw it up. It all worked out in the end.

Oh, if you're wondering what a Quickshifter is, it's basically a function of the Bazzaz (and others') electronics that allows for full throttle, clutchless upshifts. Basically, when you push on the shifter pedal, a switch actuates and sends a signal to the Bazzaz unit to kill spark at the spark plugs for 60 millisecond, thus unloading the transmission and allowing it to slide into the next gear. It's pretty sweet.

More electronics. On these bikes, there is a little exhaust valve in the tail pipe operated by a servo on the stock exhaust. I think its purpose is to create backpressure at lower RPM or something. It doesn't matter, because aftermarket exhaust doesn't allow for the little valve. So you unplug it and remove it. But, the ECU wants it to be there and will throw error codes and in some cases make the bike run in "limp mode". So you have to trick the computer into thinking the servo and valve is still there. It's an easy modification made with 2 resistors and 1 capacitor and soldering wires together. Search on 600rr.net for the very awesome instructions for the mod. Or, I think you can buy a ready made version (I've heard them called "Servo Buddies" or something). I used the stock plug and made my own, soldering and isolating all the components carefully, then wrapping the whole thing in a little rubber tube to keep it safe.

Since race bikes don't have a kickstand, I had to trick the ECU into thinking the kickstand was in the up position all the time. This is super easy--you basically just have to close the circuit on the kickstand switch. BUT, on this bike, the kickstand switch will allow you to run the bike in diagnostic mode to interpret any error codes in the event your check engine light is on. Even though there is another diagnostic plug in the tail section, I felt it was important to keep the option to run diagnostics off the kickstand switch, so I jumped the wires on the kickstand side of the switch so I could just unplug it to run diagnostics. This actually helped as soon as I fired the bike up, because I had the check engine light go on. Once I unplugged my jumped kickstand switch, I saw two short blinks--which meant I forgot to plug in a hose on the Manifold Air Pressure sensor when I removed the airbox earlier in the build.

After pretty much everything was done, I mounted up the bodywork. I went with Hotbodies, because it was cheap. The jury is still out as to whether it was worth it, because the stuff came over pretty junky. In all fairness, Hotbodies said they would replace any piece I couldn't get to work or felt was unsatisfactory. I didn't make a big deal out of it and managed to make everything work. Drilling the holes was pretty straightforward, but it took a bit of finesse (and some heat to "relax" the bodywork) to get everything to fit. I used much of the stock hardware and tried to replicate all the fittings. The only special hardware was at the seat (this is a "superbike" tail section by the way). I cut one of the exhaust mounts into two huge washers and glued a bike tube to the back to act as a cushion at the mount. I also added a little cylindrical spacer at the back of the tail section (above the exhaust silencer) to allow a through-bolt into the stock subframe.

One ingenious thing that my friend, Mike D came up with (note, his ability to make random-ass tools out of crap in my garage is unrivaled) is a way to get the holes for the frame sliders to work perfectly. First off, we put a blob of grease on the bolts that hold the frame sliders on (without the sliders on, of course), then mocked up the lower section and used the resulting grease mark as a guide for the center of our hole. Using a hole-saw, I cut a hole. But it wasn't perfect, so I started sanding away. Mike D, being the smart one, wrapped some sandpaper around the hole-saw, put a rubber band around it and, voila, we had ourselves a drum sander. 2 seconds later, the holes had enough clearance for the sliders and everything fit perfectly.

Being a "superbike" style tail section, I had to make a seat. I just bought a square sheet of glue-backed foam from Lockhart Phillips, made a template out of paperboard, roughed it out with a knife, smoothed it out with a dremmel, and finished the edges by hand sanding with 180 grit sandpaper.

Oh, and I painted it. That whole experience is worth its own blog post, so I'll leave theose details for later. I will say, what started as a last-minute place to paint my bodywork, ended up being an amazing experience with some of the coolest people I've ever met... and a ride on a custom right-side shift, Triumph board-tracker with no front brake. It was like finding Shangri La.

The build was a lot of work--mainly fiddling with this and that, and figuring out where to put all the damn wires. Despite the time, the built came out awesome and it's really functional, user-friendly race bike now!

Before:

During:

All that's left is to ride it...

This comment has been removed by the author.

ReplyDelete